Now that my 8×10 camera is getting heavy usage (Kari is out in the field with it as I type) I have been working on either repairing pinholes, making parts so it can be used (such as these new lensboards) or making things to protect it. The latest product: a custom ground glass protective cover.

First off, I put the sheet of acrylic in the laser to cut out the basic shape. And while it’s in the laser, might as well etch my name and website.

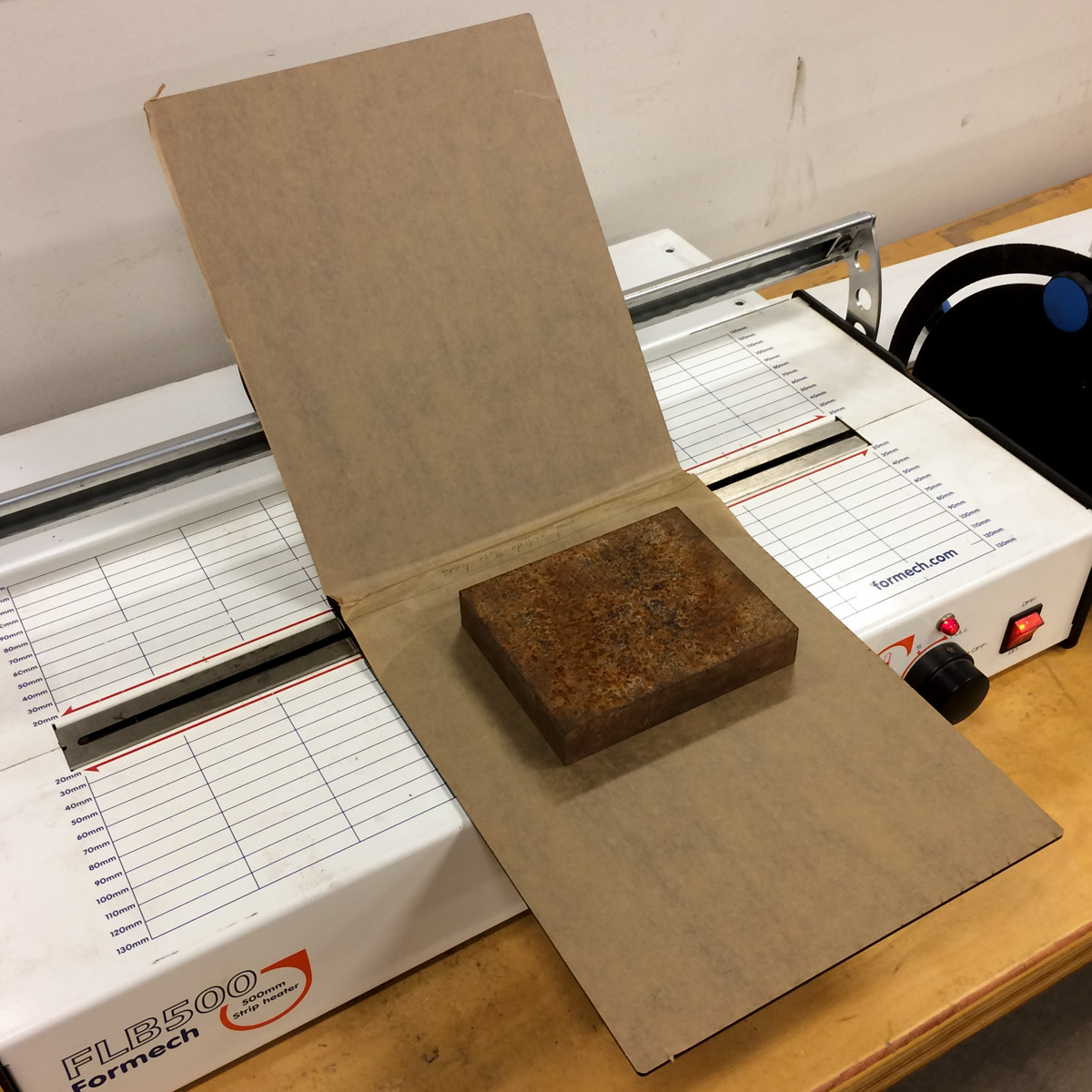

Then came time to learn something new: heating and bending the acrylic into shape. TechShop has tools for that, which are really pretty simple, actually: a strip of metal that heats up in a nice straight line, and a hinged thingy that one can set to the desired angle. Heat up the acrylic, press into the form, wait for it to cool.

Funny story: I made the first 90 degree bend easily, and was fairly proud of myself. I put the acrylic back on the heat strip for the second bend and thought “I gotta document this process” and then text it to a couple friends and stuff. I finally realized, while attaching the photo to the text, that my original 90 degree bend was slowly drooping under the heat. Ooopsie.

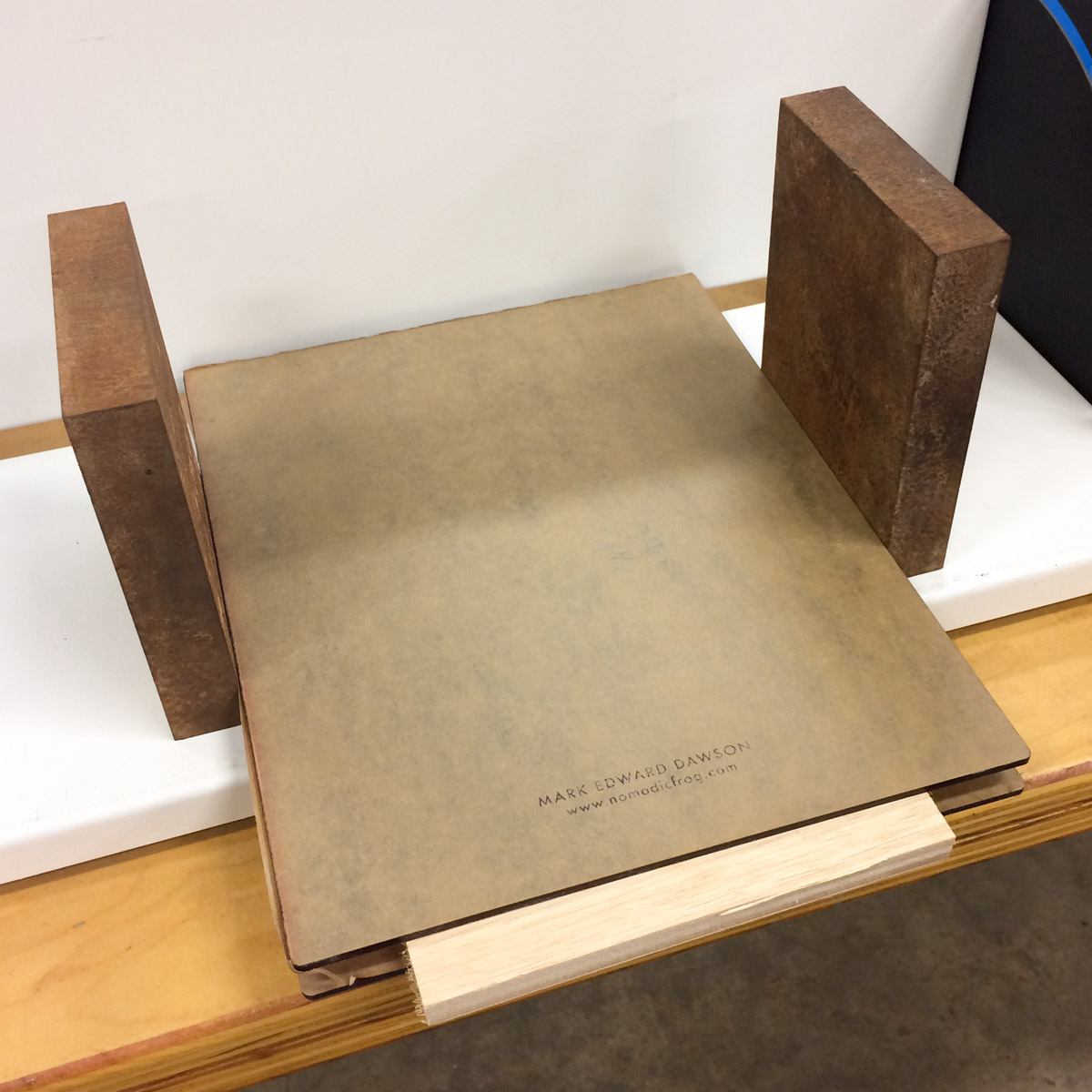

Got a couple of heavy steel bricks, propped it up, got the new bend made, cooled, done! As often happens at TechShop, I had a goofy grin on my face after learning something new and using it to make something that turned out roughly as I planned – and it works as planned too!

The fact that it is red is just because why not? At the time I bought the acrylic, under time pressure, there wasn’t any opaque black available. I figure the cover is going to get scratched and smudged pretty quickly, and a different material would not show it as much, but for now it’s pretty and red, and it’s more about function – protecting the glass – than form. Plus, it makes a subliminal connection to the darkroom, right?