About the same time I was working on my I-beam coffee table I was also creating another toe breaker / boat anchor, my Big Beam Bench.

The wood beam was left over from a set of end tables I made for a customer. I was sitting in my very small and cluttered office I staring at it and thought “I should make something with it to get it out of here”. The beam bench idea was born.

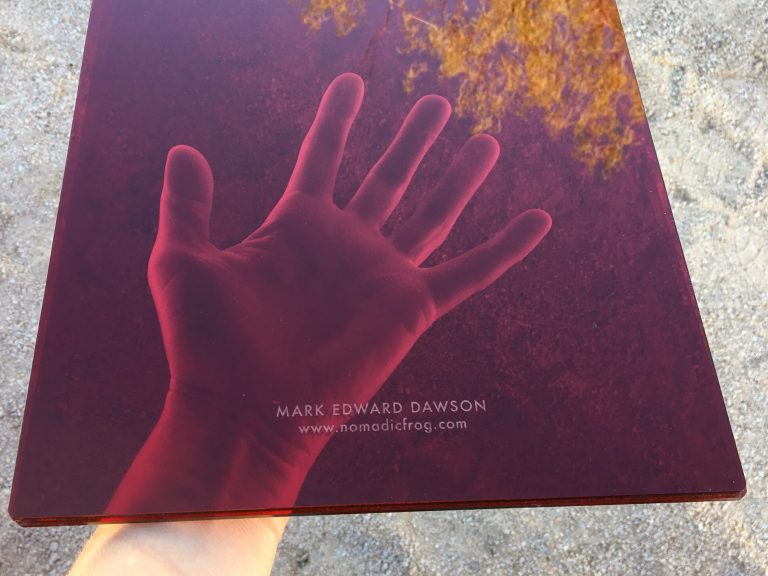

I left the pine beam exactly as I found it, aside from squaring off the ends and sanding them smooth. On one side there is a hole, with an old wooden peg, that used to form a joint in whatever structure this came from. I do sometimes give the wood beams a quick blast in the sandblasting cabinet – gives them a certain texture, as well as removing dirt and loose bits.

The legs are 3/8” thick, 12” wide steel plate, which I had fun cutting, as if it were warm butter, on this nifty machine called an “Ironworker”. I then welded them together to form the bench’s legs.

John, one of the other TechShop members, took an interest in the large pieces of wood I was working with, and talked to me a bit about them and the various characteristics of different kinds of wood. We discussed options for treating this one, and I mentioned I didn’t really want the polyurethane to darken it as much as on other things I’ve made.

This beam is really interesting, to me, because one side is a darker rich reddish tone, and the opposite side is a pale yellowish-green. It looks like an old piece of wood from some saloon or blacksmith’s shop out here in the west, that has been walked over by thousands of feet over the past 100 years. I didn’t want to change that color any more than necessary.

John suggested perhaps first putting on a coat of shellac before the polyurethane, and I gave it a try. I’m in love. The straw colored piece of the wood looks wonderful, and the deep red portions look like well-loved leather, chocolate, I dunno what. Just fantastic, I think.

As with all of my furniture, this piece is for sale we’ve decided to keep it. I would also be overjoyed to make one to your custom specifications. Any excuse to go hunting for interesting pieces of wood, or to put the welding helmet on and make sparks fly! (Update: unfortunately the shop where I made these has closed, and for the time being I am unable to make more. Some day!)